Continuous Motion Hang Tag Applicator Machine

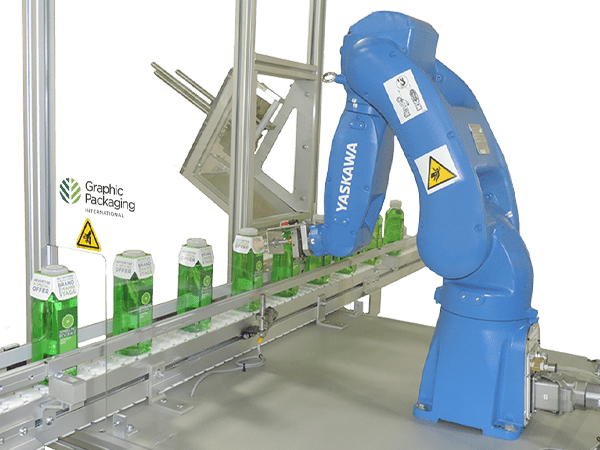

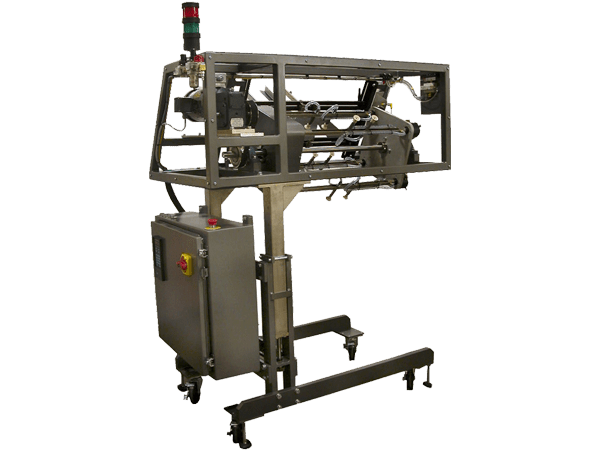

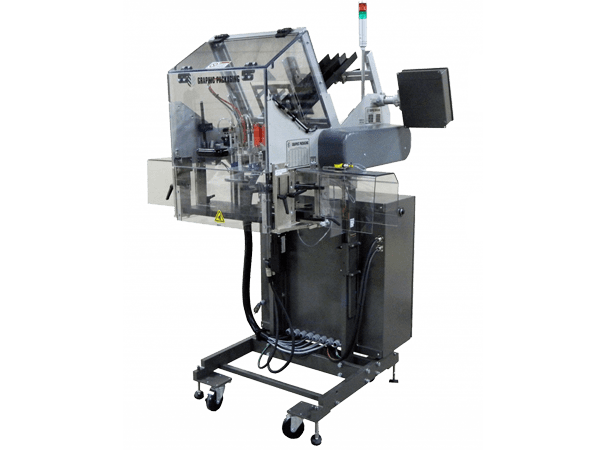

The continuous motion hang tag applicator machine provides flexible, high-speed, continuous application of neck or hang tags to bottles. The machine can be standalone or can be integrated into your current production line.

The machine can apply various types of hang tags, including paper, paperboard, and plastic, as well as different shapes. Product size will be dependent on machine design.

Convenience benefits include clear visibility with guarding that provides easy access to machine.

Finishes. enhancements, and capabilities include three construction grades to match application needs, including water-resistant/wash-down.

Quick Links

See the Continuous Motion Hang Tag Applicator Machine in Action

A flexible, high-speed, continuous application of neck or hang tags to bottles that can accommodate various tag types and shapes.