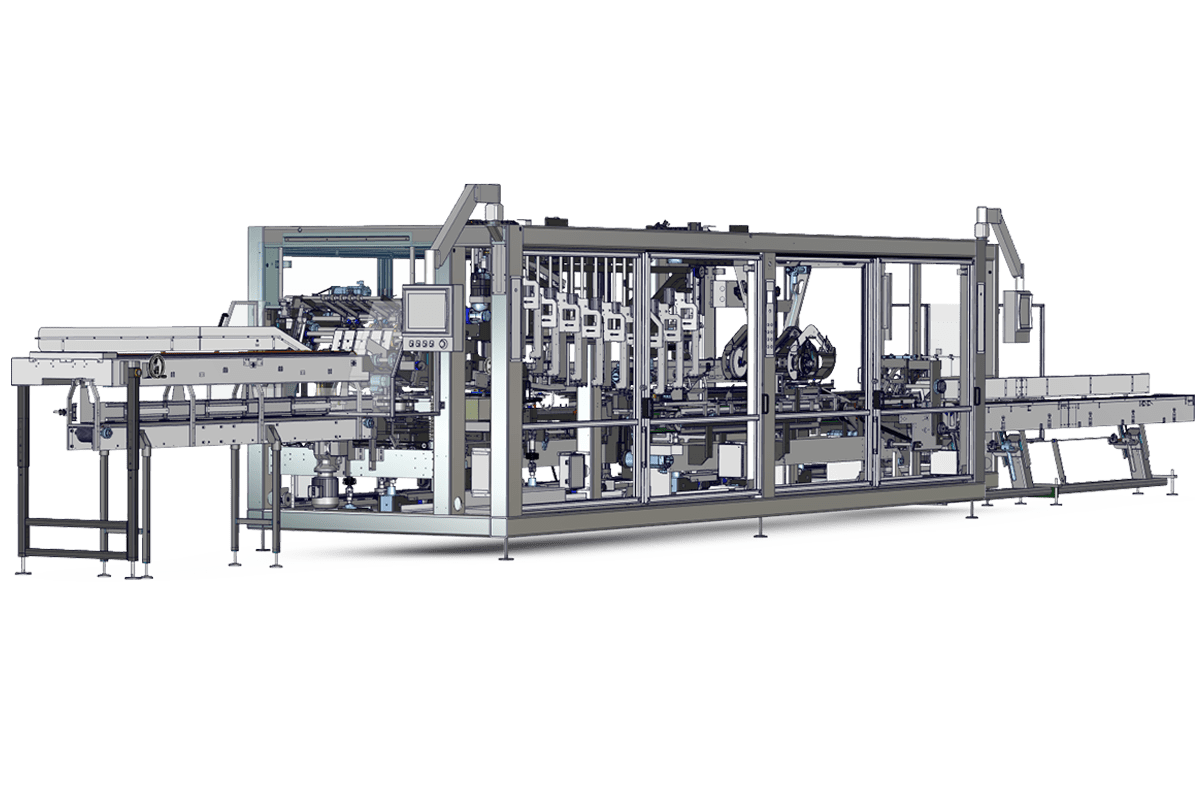

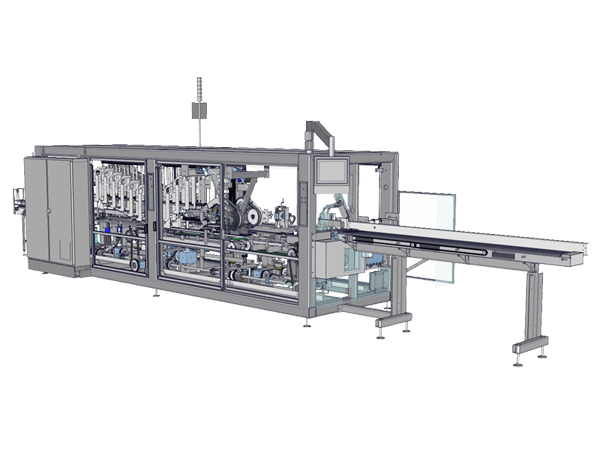

AutoMaxx™

A high-speed, compact packaging machine developed from a combination of the Marksman™ X5 wrap system and the AutoFlex™ 1500HS basket system, AutoMaxx™ can produce both wraps and basket carriers. It is suitable for a range of glass and PET plastic bottles and aluminum cans in various configurations, including over-the-crown and neck-through wraps, as well as open, neck-through, and fully enclosed baskets.

It is a fully servo-driven machine split into three zones: the common product zone, the wrap zone, and the basket zone. When either the wrap or basket zone is running, the other pack zone is parked.

Highly efficient and with fewer parts, AutoMaxx simplifies and reduces maintenance. Changeover is tool-free, improving operations and enabling a changeover time of just 15-30 minutes.

Quick Links

See AutoMaxx in Action

A high-speed, compact packaging machine developed from a combination of the Marksman™ X5 wrap system and the AutoFlex™ 1500HS basket system, AutoMaxx can produce both wraps and basket carriers.

AutoMaxx Features

Standard Features

- Corrosion-resistant components and heavy-duty welded tubular painted steel frame

- Full height, clear sliding guard doors providing easy walk-in access to the machine for changeover and maintenance

- 10ft (3m) laned product infeed conveyor

- Starwheels and planetary selector

- 18ft (5.5m) low level basket magazine – 1,600 basket capacity

- 10ft (3m) wrap magazine – 5,500 wrap capacity

- Vertical basket chutes with bottom lug basket feed system

- Segment wheel feeder for wraps

- Basket repitching system to achieve high pack throughput at reduced speeds

- GPI standard lock

- IQ Tablet with changeover checklist with videos and complete parts manual

- Automatic Prime and clean out features

- Venturi vacuum generator

- Integrated turn/divide/reject system

- Automatic oil system with low level alarm

Optional Features

- Lock inspection with or without pack reject

- Low-level wrap feeder (LLF) for ergonomic magazine loading

- Dynamic handler pusher

- Tab locker

- Automatic basket decaser option

AutoMaxx Applications

Applications Include:

- Beer

- Craft beer

- Carbonated soft drinks

- Water and sports nutrition

- Coffee and tea

- Wine

Related Machinery

AutoFlex™

The AutoFlex™ basket multipack machinery system is a compact, high-speed lock-base basket system that can package a wide range of glass and PET bottle sizes in various pack formats and styles.